Overcoming Spare Parts Challenges in the Underground Mining Industry

Getting genuine spare parts and components in the underground mining industry can be a challenging task. Due to the harsh and remote nature of underground mining operations, equipment is often subject to high levels of wear and tear, and replacement parts and components are needed on a regular basis. However, obtaining these parts can be difficult due to a number of factors.

This article explores the different challenges that a mining company can face to get spare parts and components.

The three main challenges

Getting genuine products

One of the main challenges is the lack of quality assurance for replacement parts and components. Some suppliers may not provide 100% genuine parts and components. This can lead to issues with the quality and reliability of replacement parts, which can lead to equipment downtime and increased costs.

The lack of availability

Additionally, mining companies struggle in obtaining spare parts and components in the underground mining industry due to the lack of availability of certain parts. Many underground mining operations are located in remote areas, which can make it difficult to access parts and components from local suppliers. Additionally, some mining equipment is specialized and not widely used, making it difficult to find replacement parts.

Purchasing at the right price

A third challenge is the high cost of replacement parts and components. Due to the specialized nature of underground mining equipment, replacing parts and components can be expensive. Additionally, the cost of transportation and logistics can also be significant, as parts and components may need to be shipped long distances.

The different solutions to these challenges

To overcome the challenges of obtaining spare parts and components in the underground mining industry, several solutions can be implemented. One solution is to establish a comprehensive inventory management system that keeps track of the availability of spare parts, including their location and lead time. This can help minimize equipment downtime by ensuring that the right parts are readily available when needed.

Another solution to overcome the challenges of obtaining spare parts and components in the underground mining industry is to anticipate the needs of the mining operation and maintain adequate stock levels. By analyzing equipment usage and wear and tear patterns, underground mining companies can predict which spare parts and components are likely to be needed and order them in advance

SmartParts®: Genuine Spare Parts & Components by Aramine

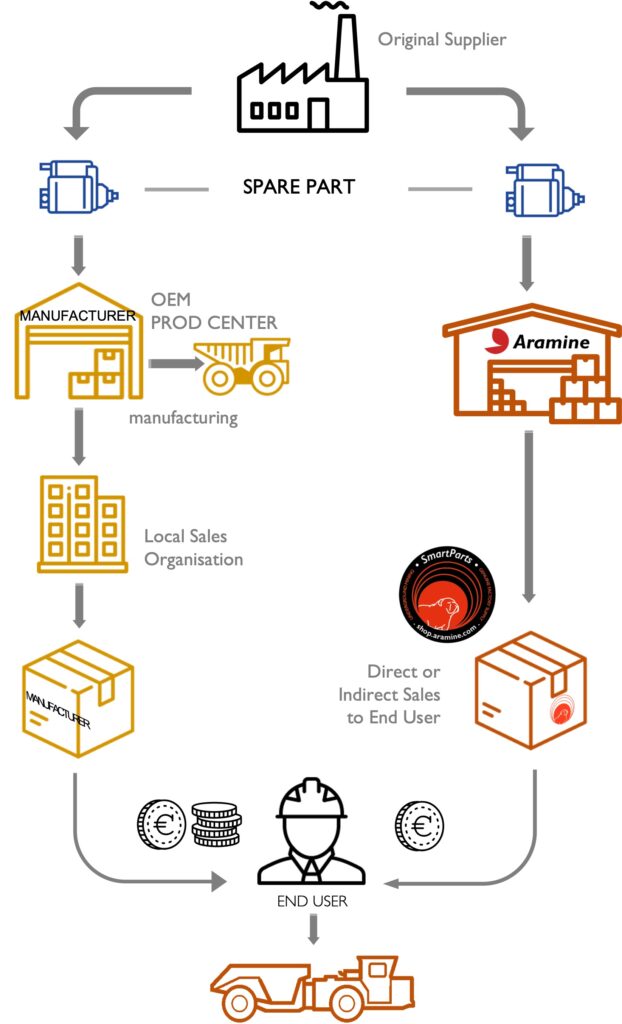

Aramine SmartParts® program is the only alternative source of genuine spare parts and components.

After 40 years of remanufacturing used machines, Aramine is able to provide parts and components for any underground mining machine. Working directly with genuine factories and suppliers, Aramine provides 100 % genuine parts and complements.

Additionally, this shorter road map allows the company to reduce costs and offer original quality products at more competitive prices.

With 3 warehouses in the world, 1.5 million computerized references, and 800.000 available in stock, Aramine’s parts and components program allows immediate availability anywhere, anytime. With a 6,000 m2 logistics center and a stock of €18 million in parts, Aramine offers unrivaled responsiveness and performance.

In conclusion, obtaining genuine spare parts and components in the underground mining industry can be a challenging task due to the lack of availability of certain parts, the high cost of replacement parts and components, the lack of quality assurance for replacement parts and components, and long lead time of some spare parts and components.

Many underground mining operations are located in remote areas, which can make it difficult to access parts and components from local suppliers.

Additionally, some mining equipment is specialized and not widely used, which can make it difficult to find replacement parts. The lead time of some spare parts and components can be long, which can cause delays in the mining operation.

Therefore, it is important for underground mining companies to have a well-planned and organized spare parts management system to minimize downtime and ensure the smooth running of the mining operation.