The Benefits of Choosing Remanufactured: a Second Life for a Mining Equipment

When it comes to purchasing mining equipment, mining companies only have a few options. One of them is to purchase brand new equipment directly from the manufacturer. However, another option that is becoming increasingly popular is to purchase remanufactured mining equipment. In this article, we will present the benefits of opting for a remanufactured mining machine over a brand new one.

A reduced cost

First and foremost, the cost is for sure the most critical factor to consider when purchasing mining equipment. Buying a brand-new machine is usually expensive, and for many companies, it may not be financially feasible. On the other hand, purchasing a remanufactured machine can save significant money. Remanufactured equipment is mostly sold at a much lower price than brand-new equipment, making it more accessible to a wider range of companies. For instance, Aramine remanufactured equipment is on average 30% lower than a brand-new one.

A sustainable solution

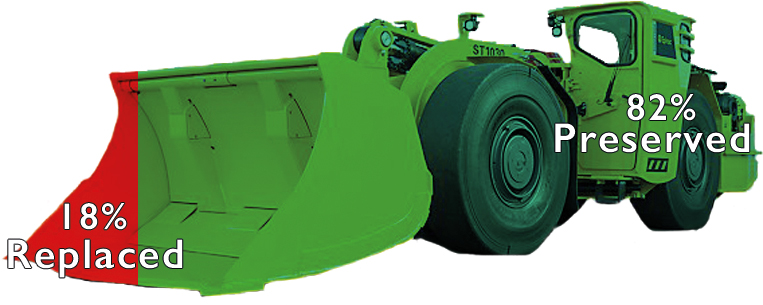

Another benefit of getting remanufactured mining equipment is the reduced environmental impact. Manufacturing brand-new equipment requires a significant number of resources and energy, which are usually harmful to the environment. Usually, most of the steel is retained which can represent over 80% of the original quantity of a machine (see example on the right). By purchasing remanufactured equipment, a machine starts its second life in a more sustainable way.

Tested and controlled

Additionally, remanufactured mining equipment is always as good as brand-new equipment. Refurbished machines have been rebuilt and tested to ensure they are in perfect working condition. They are also typically covered by a warranty to ensure that the equipment will perform as expected. Many remanufactured machines are even upgraded with the latest technology to improve performance and efficiency.

Aramine remanufacturing program

For almost 30 years, Aramine has been a pioneer in remanufacturing used equipment. Following the original specifications and using only genuine spare parts and components, Aramine remanufacturing program follows a 10 steps process that ensures a complete refurbishment of any underground mining equipment. To make sure that the equipment meets the highest level of efficiency, Aramine-trained technicians run several tests and controls on a test track. Finally, every remanufactured equipment comes with a full warranty (12 months on the frame & 6 months on the powertrain).

To conclude

In conclusion, buying remanufactured mining equipment has many benefits over buying brand-new equipment. It is a cost-effective solution, is more sustainable, can perform as well as brand new one, and can be customized to meet specific needs. Today, over 450 machines remanufactured by Aramine are living their second life underground.