How the mining sector is moving towards sustainability

Mining has environmental, social and economic impacts that manufacturer can no longer ignore. Business as usual must evolve towards economics model respecting environment and stakeholders. What are the main impacts of the sectors ? How to answer it ? The article aims to outline some tracks to create sustainable mining practices and how Aramine solutions contribute to this objective.

Having a vision for sustainability

CSR (Corporate Social Responsibility) approach allows companies to assess their practices and performance on various sustainability and ethical issues. CSR holds on 3 pillars: Environmental (reducing carbon footprint, greenhouse gas emissions…), Social (Employee benefits, adhering to labor laws…), and Governance (Risk management, ethical business practices…). Having an ESG program is crucial to implement systems and processes to measure, analyze and manage businesses’ impacts on the environment, their employees, and stakeholders. Aramine declined its CSR approach into a vision, following 3 focuses:

- Innovating for sustainable mining

- People fulfillment through expertise

- Investing in a better world

To embrace this vision and share it with all members of Aramine, a group of passionate CSR ambassadors has been created.

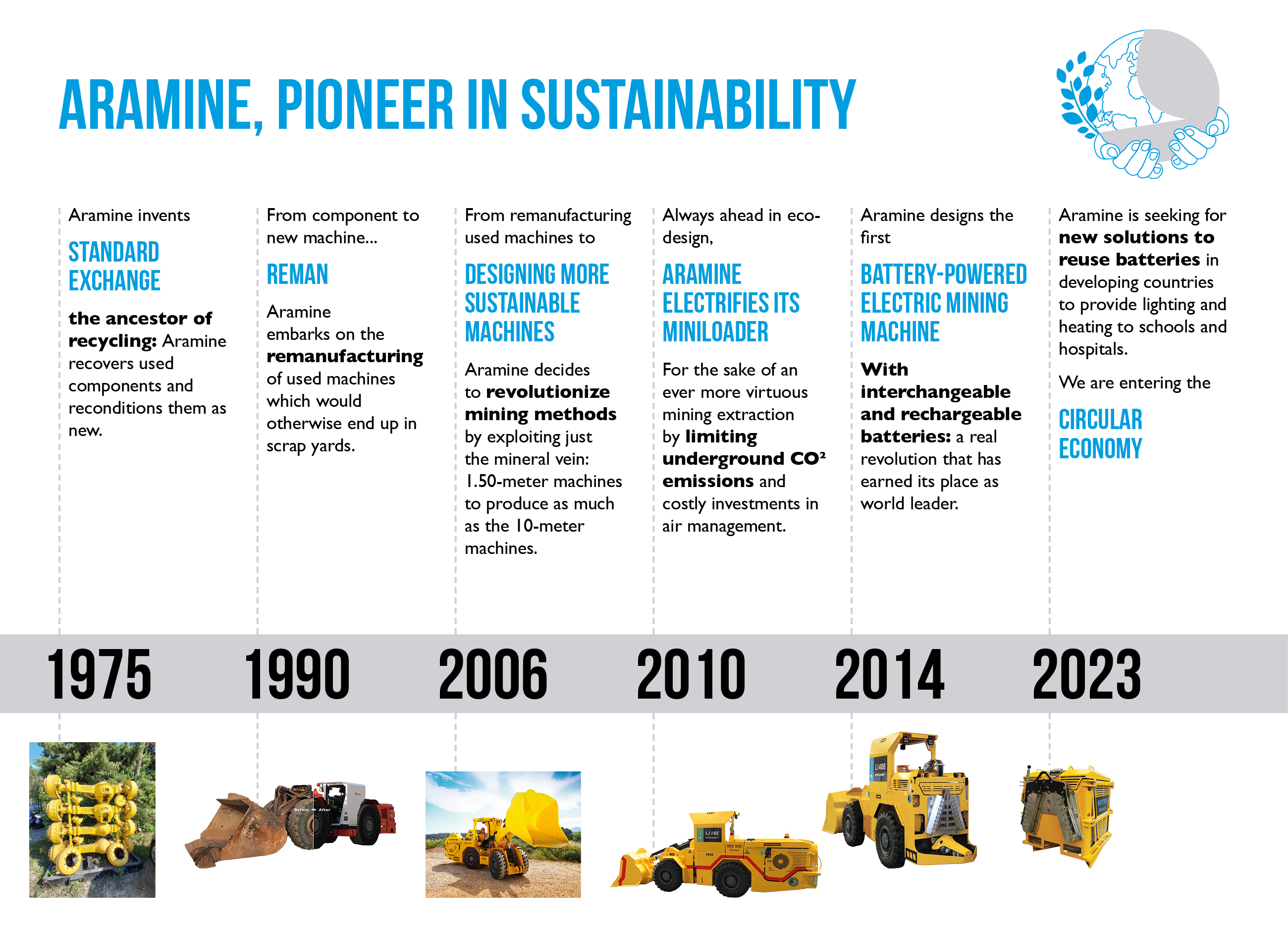

Electrifying mine

One of the key components of sustainable mining is the use of renewable energy sources. Electrifying the mine is the next step towards sustainable mining. To do so, mining companies can count on battery-electric equipment. Battery-powered machines do not reject greenhouse gas into the galleries which considerably reduces mine carbon footprint. Moreover, using battery-powered mining equipment improve minors’ working conditions while delivering more efficiency. In 2016, Aramine launched the first battery-powered mining loader, with an innovative changeable battery-module system, the L140B. Ever since the company has had the largest fleet of battery-powered loaders in underground mines around the world. Switching to battery comes with many advantages that increase the efficiency of mining operations.

In addition, many mines consume large amounts of energy, and traditional sources of energy such as coal and oil are environmentally damaging. By using renewable energy sources such as solar, wind, and hydropower, mining companies can reduce their carbon footprint and improve their energy efficiency.

Technology at the service of sustainable mine

Technology is also a key aspect of sustainable mining. Advances in technology can help mining companies to improve their efficiency, reduce their environmental impact and improve their social and economic performance. The use of autonomous or radio-controlled mining equipment can increase productivity, improve safety and reduce labor costs. Additionally, the use of IoT and big data analytics can help mining companies to optimize their operations by collecting and analyzing large amounts of data. This information can be used to improve the efficiency of mining processes, increase the longevity of equipment, and reduce costs. Aramine underground mining equipment uses a CAN-Bus control system to easily collect and analyze performance data.

Another approach underneath the surface

Mining activity consists in digging galleries to extract different materials such as ores and metals. After separating the minerals from the rest, the leftover is considered waste. To reduce the quantity of waste, mines can change their extraction process to a narrow vein mining method. By keeping the galleries’ width, the narrowest possible, mines drastically reduce the waste and can follow the vein of what they are mining for. Aramine is specialized in narrow vein mining equipment the width does not exceed 1.5m.

Another important aspect of sustainable mining is water management. Mining operations often use large amounts of water and can have a significant impact on local water resources. By recycling and reusing water, mining companies can reduce their water consumption and minimize the impact of their operations on local water resources. Additionally, the use of dry stacking and dry tailings facilities can also help to reduce water consumption.

Recycling and remanufacturing

Due to hard conditions in underground mines, mining machines have a short lifecycle. Unfortunately, much-used equipment is left underneath the surface, and tons of steel are buried in the mine. Aramine decided to look into finding a solution to this waste. In the early 90s, the company started to remanufacture used equipment and offer them a second life following the original specification : Aramine remanufacturing program was born. The advantages of getting remanufactured mining equipment are various in addition to saving metal.

Rehabiliting the mine

Rehabilitation and land reclamation are also important components of sustainable mining. After mining operations have been completed, the mined land must be rehabilitated to minimize its impact on the environment and local communities. This includes restoring the land to its natural state, planting native vegetation, and creating new habitats for wildlife.

Conclusion

Sustainable mining is a complex and multi-faceted concept that requires a holistic approach. It involves balancing the economic, social, and environmental aspects of mining operations. By adopting sustainable mining practices, companies can improve their environmental performance, reduce their social impact, and increase their economic performance. Attaining a sustainable mining industry is possible if mining companies change their approach, from the extraction method, to the mining equipment. At Aramine, they believe in a global performance.